Just the way movies have ‘Behind The Scenes’, Movie Screens too.

We all see the Big Fascinating Cinema Screens (that’s probably the reason we all go to theaters, isn’t it?) but how many of you know what goes behind creating it?

Since that’s what we do day in and day out at Galalite Screens, we thought why not capture the procedures that happen at the back & share them with you all!

Wondering how the journey evolves and how is the final screen delivered to our customers?

Here’s a wide overview we’re here to share with you today –

Importing the PVC Fabric

The first part of the process includes importing the fabrics required to make the cinema screen from Europe to India. These are flexible PVC fabrics that are ordered in rolls of width 1.60 meters / 5 feet approximately.

Why PVC fabric?

PVC fabric is formulated specifically as per premium stands of Galalite Screens. The manufacturing of this fabric follows our special guidelines, approvals & details for the desired outcome. The reason for us to choose PVC is the fact that it contains optical brighteners that improve the uniformity and brightness of the reflected light from the projector. Exactly what Galalite Screens’ USP stands for!

Perforation Process:

Once the PVC rolls arrive in India, they are loaded onto the perforating machine that helps perforate the fabric to Galalite’s unique patented design.

Why the perforation process?

The perforation helps the sound to pass from the center channel speakers which are located behind the screen without a significant amount of sound loss. These speakers are the main dialogue speakers. The perforation also helps the heat and light pass through the projector.

Procedure at the factory:

After placing an order to the factory, the PVC fabric rolls are cut as per the height measurement of the screen. Once cut into this ratio, the parts are joined as per the width measurement of the screen.

To help you understand with an example –

If the screen is 20ft * 40ft, the PVC fabric will be cut into 8 parts of 20 feet and joined as per the width measurement to form a complete screen. You must be wondering if the process of joining the parts will leave any marks. Being very well aware & alert of this concern, we use our highly effective seam welding process to make those joints completely invisible. Once this is done, the screen edging is created & grommets are fit onto the edge of the screen. This step makes it easy for tying the screen fabric to the frame.

How are different screens packaged & dispatched for delivery?

Our Matte White Screen is ready for packaging & delivery once the above procedure is complete.

There are a few more steps involved when it comes to our Digilite Screen (pearlescent coating) & Prism (silver coating).

They are tied onto a wooden frame in our coating plant, the maximum size being 9.5mtrs x 19mtrs (30ft x 60ft). After this, the screen is coated in our completely automated coating plant which is imported from Germany.

Galalite Screens is the only Indian cinema screen manufacturer to have a fully automated coating facility & an in-house automated perforating machine.

Since the Prism 3D cannot be folded, it is rolled along with the height of the screen for the packaging & transport. Otherwise, our regular silver screens are packed in a cardboard core which is the most strong & reliable for export. For this, special wooden boxes are created on-demand and are provided with customized packing. The packaging & the transport for Digilite Screen is the same as the silver screen.

The Matte White, Digilite 1.4 & 1.8 can be folded while sending for transportation. A cardboard box stitched with a hessian material around it is what is usually preferred to pack them.

And we’re done with the packing!

Although our job ends here, we’re always excited to know how our audience loves the screen & how it makes their cinema experience super special!

We hope the next time you watch the movie on the big screen, you acknowledge the behind the scenes of the movie screen as much as you always do for the movie!

We would be happy to answer if you still got any questions about the journey of a cinema screen. Comment them below!

FAQ’s

How are cinema screens made?

Cinema screens are crafted using precision-coated materials for optimal light reflection, contrast, and durability.

What materials are used in cinema screen manufacturing?

High-quality PVC, woven fabric, or perforated surfaces are used to enhance image clarity and sound transparency.

Why are some cinema screens perforated?

Perforations allow sound to pass through, ensuring seamless audio-visual synchronization in theaters.

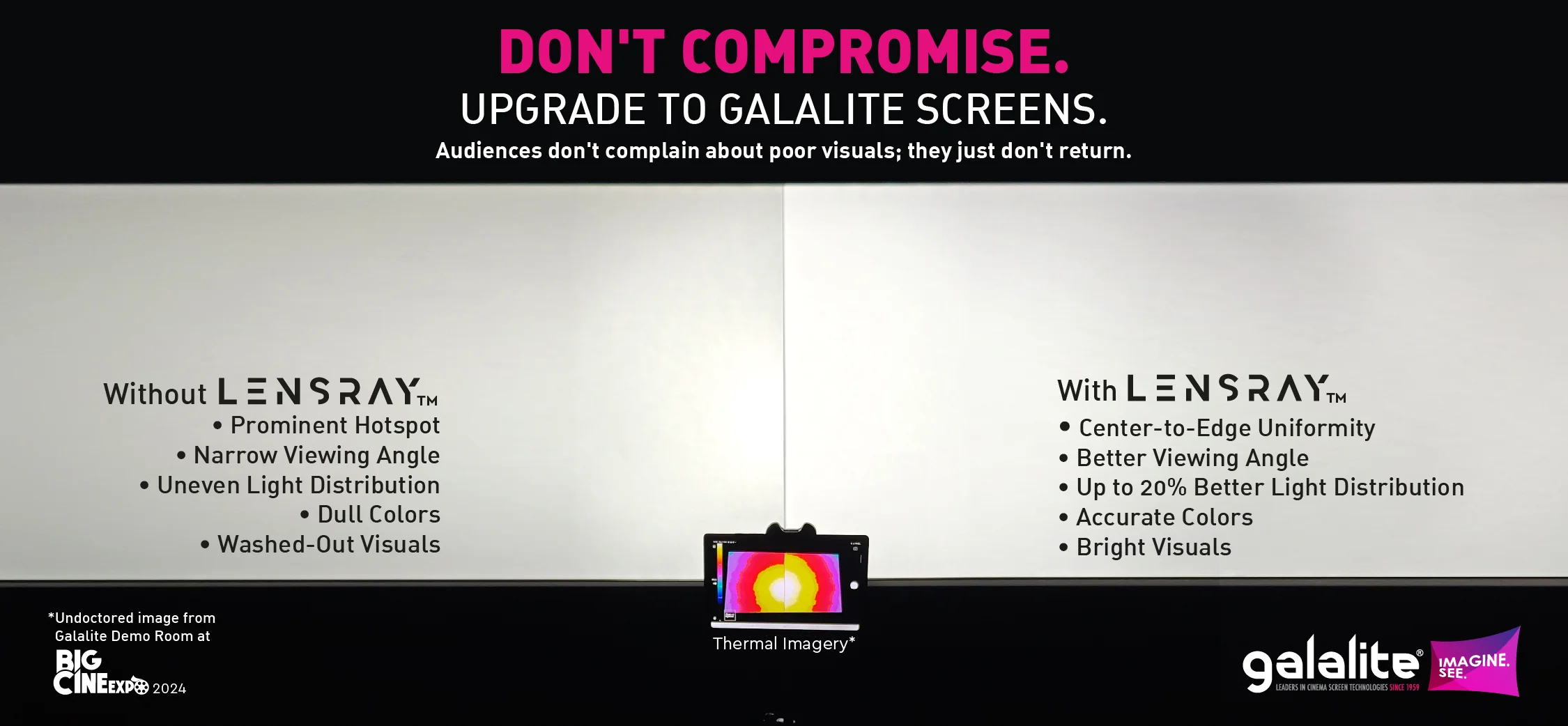

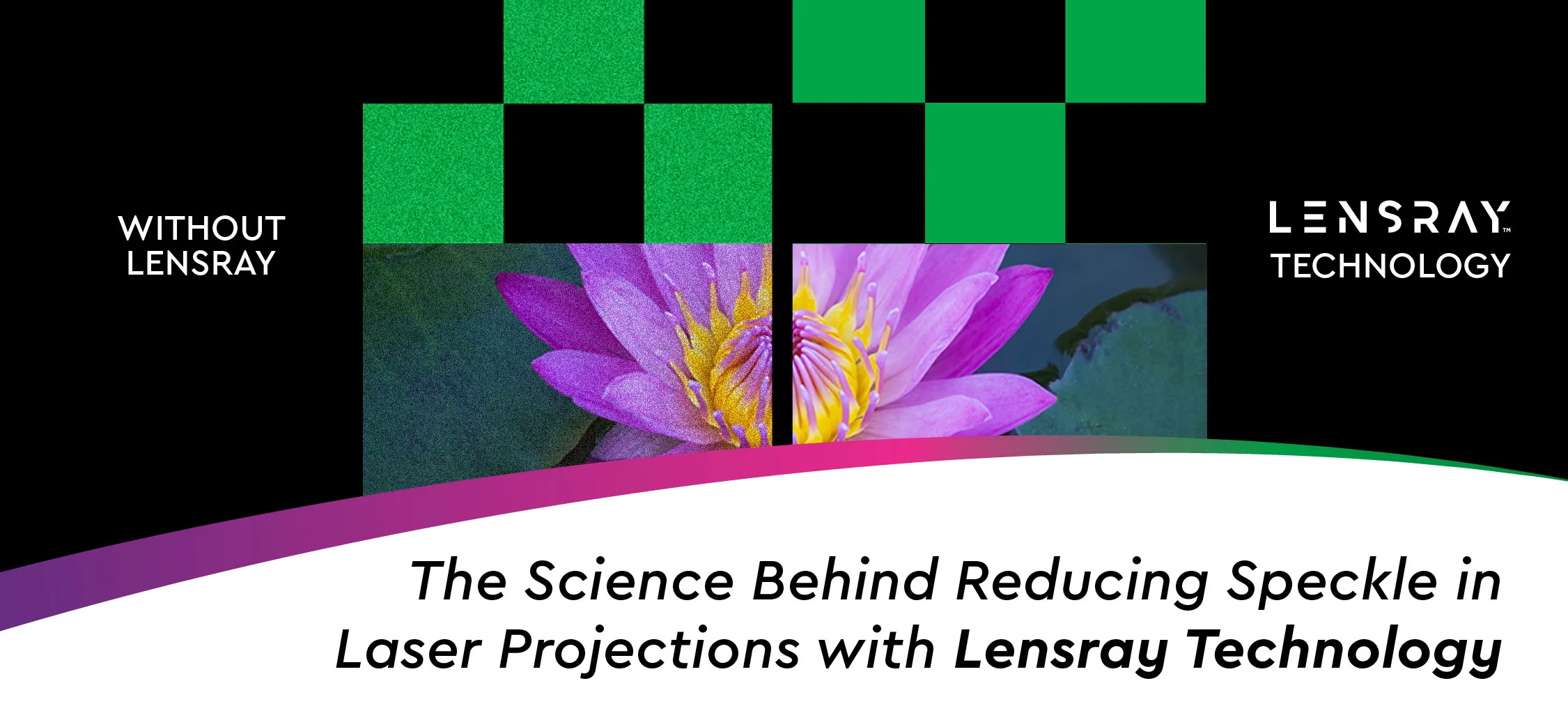

How does screen coating impact movie quality?

Special coatings enhance brightness, contrast, and viewing angles for a superior cinematic experience.

What is the lifespan of a cinema screen?

With proper care, a high-quality screen can last several years before requiring a replacement.