Galalite, the pioneering manufacturer of cinema projection screen surfaces, has been at the forefront of innovation and technology for over six decades. At the beginning of the year, the company has taken a step towards reducing its carbon footprint and improving sustainability by investing in an Air and Water Pollution Control system in their plant.

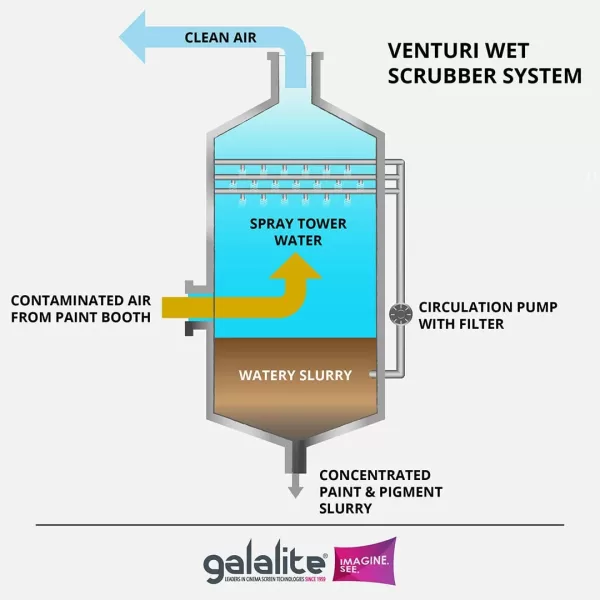

During the production of Avatar, Galalite’s factory operated around the clock to meet the demand. Following the success of the film, they temporarily closed the plant to undergo significant upgrades. For a period of two weeks, the factory was closed while they successfully commissioned and installed a wet scrubber system. A wet scrubber is a mechanical system that removes pollutants from an air stream by bringing it in contact with water. Wet scrubbers are generally the only single air pollution control device to remove particulates and gases/vapors. They are highly efficient at capturing the smallest dust particles and can eliminate more than 99% of airborne particulate matter. Galalite redirects the cleaned air back into the plant to reduce the environmental impact further and make it into a zero-emission plant.

Yusuf Galabhaiwala, Director of Operations at Galalite, says, “We believe in doing our part to create a cleaner, more sustainable world. Although this was a major investment, we didn’t hesitate to invest in this system, even if it meant temporarily shutting down our plant although the markets had just bounced back. It was worth it to know that we’re doing our best to protect the environment.”

Galalite has been committed to using eco-friendly water-based coatings since 2009 and was one of the first companies to adopt such sustainable practices.

Water-based optical coatings are eco-friendly and have low VOC levels and HAP emissions, reducing the concentration of contaminants in the ozone layer.

Galalite has always believed in constantly upgrading its technology and processes, and this new development of installing a scrubber is no exception. Galalite has also slated other upgrades and initiatives that further reinforce its commitment to innovation while being sustainable. The company plans to launch new products in the near future that will enhance and upgrade the movie-watching experience while being environmentally friendly.

Saikat Ali, Production Head at Galalite, added, “Upgrading is constant at Galalite. We are excited about the new products we will soon launch, and we are confident that they will further elevate the movie-watching experience. As always, we will continue to innovate and take a responsible approach toward the environment.”

With these initiatives, Galalite hopes to set an example for the industry and inspire others to adopt sustainable practices. Galalite’s commitment to sustainability and the environment is commendable, and it is a prime example of how businesses can innovate while keeping the planet in mind. With its cutting-edge technology, innovative products, and eco-friendly approach, Galalite is a true leader in the cinema screen industry.

About Galalite:

Galalite is a family-owned business headquartered in Mumbai, India, and is the leading manufacturer of cinema screens in the country. The company has the largest production unit in Lonavala and is now a global leader in cinema screen manufacturing in European countries. With a commitment to innovation, quality, and sustainability, Galalite has become one of the largest projector screen suppliers in the world, representing India on the global stage.

FAQ’s

How is Galalite setting a new standard for environmental responsibility?

Galalite adopts sustainable manufacturing, eco-friendly materials, and energy-efficient processes to reduce its environmental impact.

What eco-friendly initiatives has Galalite implemented?

Galalite focuses on waste reduction, recyclable materials, and energy-efficient production to promote sustainability in cinema screen technology.

Why is sustainability important in cinema screen manufacturing?

Sustainable practices help reduce carbon footprints, conserve resources, and create environmentally responsible cinema solutions.

Does Galalite use recyclable materials in its screens?

Yes, Galalite integrates recyclable and sustainable materials in its screen production to minimize waste and environmental impact.

Where can I learn more about Galalite’s sustainability efforts?

Visit Galalite’s website for insights into its eco-friendly initiatives and commitment to environmental responsibility.

Related articles